Allied Vision has developed its own “system-on-chip” as basis for future product lines. ALVIUM combines advanced image processing, small size, low power consumption and standard interface options.

Stadtroda, Germany, May 4, 2017 – Allied Vision introduces a new unique vision processor technology. The ALVIUM® technology consists in a proprietary chip design optimized for advanced digital imaging combined with a comprehensive image processing library (IPL). For the first time in this industry, a camera manufacturer performed a paradigm change and created its own system-on-chip.

Revolutionary ALVIUM® technology makes the impossible possible

Acknowledging the rise of embedded systems as an alternative for PC-based systems, Allied Vision’s engineers have completely reinvented camera architecture to create a technical platform that provides the best of both worlds:

- Broad sensor variety

- Advanced image pre-processing

- Compact form factor

- Low power consumption

- Industry standards

- Excellent price/performance ratio

To achieve that, Allied Vision created its own “system-on-chip”. The unique ALVIUM® technology reflects the best of 25 years expertise in digital image optimization and camera control. It is the core of the new Allied Vision 1 product line.

The ALVIUM® image processing library has three feature levels, offering a pool of features related to basic camera operations, a nice image quality and camera application functionality respectively.

The ALVIUM® technology does not require proprietary or customized interfaces. It builds on established standards. It supports two standard interfaces to connect to PCs and embedded boards: MIPI CSI-2, the standard camera interface for embedded systems, and USB3 Vision, the GenICam compliant standard for the use of USB 3.1 gen. 1 as a camera interface in the machine vision industry.

Advanced vision technology for PC based and Embedded systems

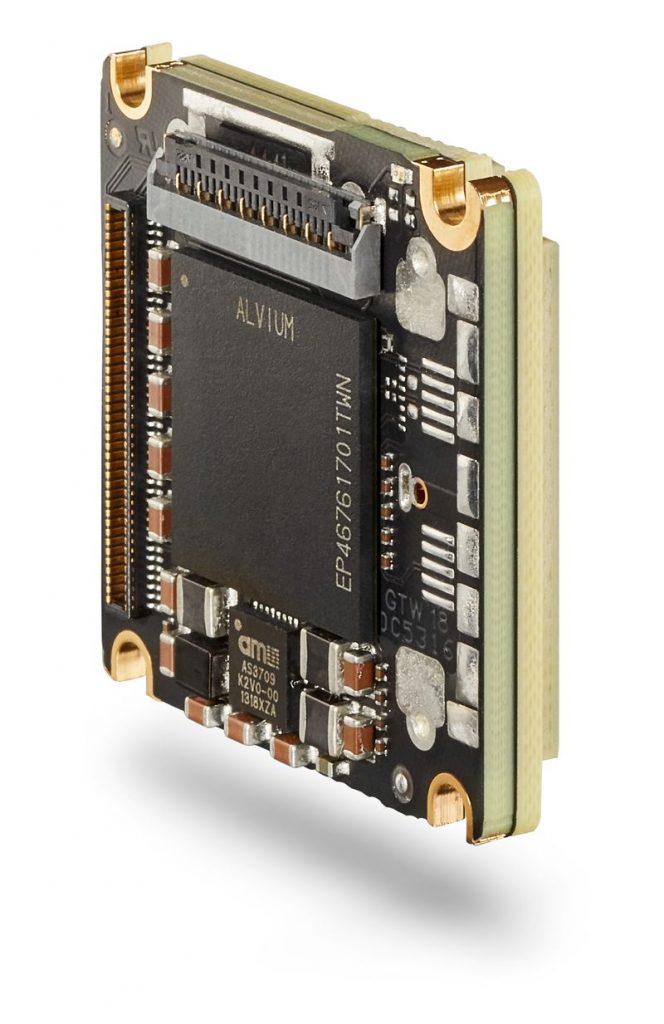

ALVIUM® technology enables Allied Vision to design a full range of cameras that provide a wealth of on-board image pre-processing functions in a small form factor. Because the chip is much smaller than an equivalent off-the-shelf FPGA, the sensor, the ALVIUM® chip, the interface and all electronics components fit on a 26.5 x 26.5 mm board. Small size and lightweight cameras are demanded by many PC-based applications. But in embedded systems, these values are even a must. So the ALVIUM® technology is the key to a high-performance embedded vision camera.

By shifting image correction and processing tasks from the host to the camera’s ALVIUM® IPL, engineers can offload the CPU on their embedded boards for alternative processing tasks. This is particularly valuable for designers of embedded systems, who need to manage the computing power of smaller processors.

Allied Vision’s ALVIUM® chip has also been optimized for low power consumption. As it can be mass-produced at a much lower cost than an off-the-shelf FPGA, it is possibe to offer high-performance, high-quality cameras made in Germany at an affordable price level. All that without compromising on image quality or camera performance and durability.

Developed by Allied Vision

ALVIUM® is an exclusive technology developed by Allied Vision and is only available in Allied Vision cameras. All cameras of the new Allied Vision 1 product line build on the ALVIUM® Technology.

Allied Vision 1 Product Line

The new Allied Vision 1 product line is a full range of digital cameras designed for embedded vision applications but fulfilling the high standards of industrial and scientific image processing also referred to as “machine vision”. The 1 product line builds a bridge between the embedded and the PC-based world. As such, it is a revolution for both the embedded and the traditional machine vision community.

More Information on: www.embeddedrevolution.com