This article was originally published at Basler's website. It is reprinted here with the permission of Basler.

You probably encountered coaxial cables in your youth, maybe from tube TVs with connections to the roof antenna or a cable connector in the living room wall. These cables are now coming back into favor. But by now, the cables are the only thing which the modern interfaces with the CoaXPress standard have in common with their venerable predecessors.

The CoaXPress (or short: CXP) standard was originally launched by six companies in the industrial image processing sector. The goal was to develop a fast data interface that also made it possible to bridge a large data volume across greater distances. The first CoaXPress interfaces were introduced at “VISION”, the leading trade show for industrial image processing in 2008 in Stuttgart. After three more years of development, CXP 1.0 was officially released as a new standard in 2011. Since then the relatively new standard has established itself in industrial image processing. This standard was developed further into CXP 2.0 last year.

An interface with the CoaXPress 1.0/1.1 standard supports data rates as high as 6.25 Gbps. The transmission speed of the new CoaXPress standard is twice as high, at up to 12.5 Gbps.

Which application areas benefit from CoaXPress?

Compared with other standards, a great advantage of the CoaXPress interface is the high data rate. The greater distances that can be bridged between the camera and computer are also valuable for many applications, offering possibilities for even highly sophisticated image processing solutions. CoaXPress is very popular especially in the semiconductor industry. In automated optical inspection (AOI) systems, for example, large data volumes must be achieved at high resolutions without significant latency. Other application areas include print inspection, food inspection, traffic technology (ITS) and medicine.

Typical application for CoaXPress: Automated Optical Inspection

CXP is not a standard interface like GigE or USB 3.0

Let’s take a look at two familiar interfaces to illustrate a unique aspect of CXP: USB and GigE.

USB 3.0 is an interface that has proven reliable in industrial image processing. The USB3 Vision standard is based on the new USB 3.0 interface that is widely available on the mass market. All new laptops, PCs and even tablets and smartphones now come with a USB 3.0 interface.

Gigabit Ethernet (GigE) has been an established standard in industrial image processing since 2006. Based on the number of installed applications, GigE is currently the most widely distributed interface technology for industrial digital cameras.

The advantage of USB 3.0 and GigE is that they don’t demand the additional integration of plug-in cards in the computer.

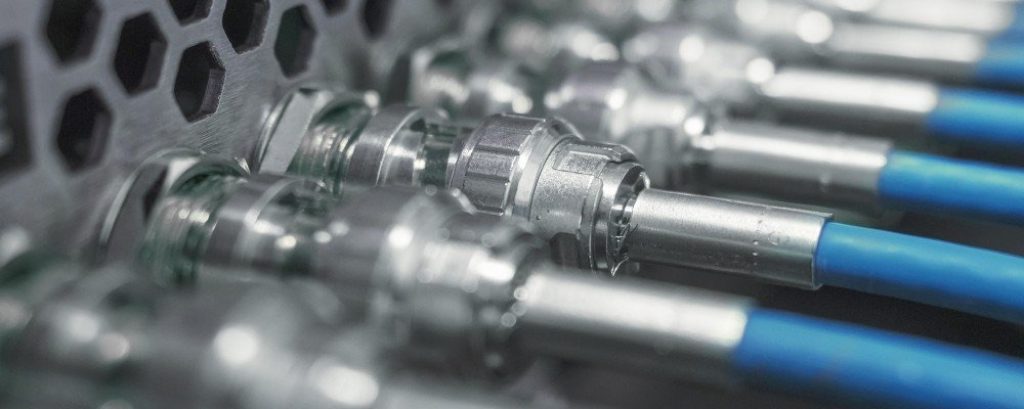

This is a huge difference to the CoaXPress standard, because here an appropriate plug-in card must always be used for the data transfer into the PC. CoaXPress is, different to USB or GigE not already part of the standard PC. A further reason for the plug-in card is the saving of CPU load: without a special plug-in card the high data rates typical for CoaXPress would load the CPU in the PC with the transfer of the image data a lot. With the additional hardware, however, the CPU is available for the application. Last but not least, the plug-in card also provides the plugs and sockets usually used for CoaXPress: for CoaXPress 1.0 / 1.1 these are BNC and DIN 1.0/2.3 and for the new CoaXPress Standard 2.0 plugs according to the Micro BNC standard.

For the CoaXPress standard, the data transmission into the computer always requires the appropriate plug-in card.

Comparison of CoaXPress interface with Camera Link interface

But how does CoaXPress compare with the longtime “workhorse” of fast Machine Vision applications, the Camera Link interface? Camera Link has been the standard for the transmission of high resolutions and frame rates for almost 20 years. The maximum transfer rate of Camera Link is 850 MB/s. Since the bus frequency is comparatively low at 85 MHz, Camera Link requires various parallel transmission channels, called taps. This makes the required cables very thick, inflexible and expensive. Furthermore, the cable length is limited to a maximum of 10 meters. CoaXPress was introduced as the successor to Camera Link in 2008.

What is the difference between the interface card and the frame grabber?

It is important to clarify what type of card must be present in the PC to connect a CoaXPress camera. Is this a type of frame grabber?

The term frame grabber originated at a time when the analog video signal still needed to be digitized in the PC. Today, however, the image is already digitized on the camera sensor and it is then transferred to the PC in digital form. The frame grabber thus only provides the digital interface (GigE, USB, Camera Link, CoaXPress) and saves the image data in the interim. Some frame grabbers can also preprocess the data, by binning or scaling. Furthermore, the data are written directly into the main memory via Direct Memory Access (DMA), without needing to go through the PC’s processor. Image data can usually be accessed from the frame grabber with specific image processing software (e.g. Matrox MIL) or standardized interfaces like GenICam. The configuration effort and costs for a system with a frame grabber are relatively high.

Camera and frame grabber

An interface card has a simpler design compared to the frame grabber. It dispenses entirely with the preprocessing and only accepts the image data through the camera connection to then store it directly in the main memory. The CPU is bypassed again via DMA, which frees it up significantly. In contrast to USB and GigE, CoaXPress is a specific Machine Vision interface; for this reason, standard PCs don’t have the hardware to connect to CoaXPress cameras. This means that an additional card is required in the PC. But by dispensing with the image processing on the interface card, the costs as well as the configuration effort here are lower.

| Property | Interface Card | Frame Grabber |

| Preprocessing of the image data (e.g. scaling) | No | Yes |

| CPU relief via DMA | Yes | Yes |

| Standard drivers/interfaces (e.g. GenICam) | Yes | Usually |

| Interfaces to image processing software (e.g. Matrox MIL) | Yes | Usually |

| Installation and configuration effort | Low | High |

| Costs | Low | High |

Summary

Large data volumes at high transmission speeds across long distances: the new CoaXPress 2.0 standard for industrial image processing makes it all possible. Designed as a successor to the prevalent Camera Link standard, this new Machine Vision interface also requires an additional interface card in the PC. Considering the large amount of transferred data, however, this is not a disadvantage – the CPU of the PC isn’t blocked by the data transmission but is fully available for the image processing application.