This article was originally published at Basler's website. It is reprinted here with the permission of Basler.

For nearly every sensor model, there is a considerable number of cameras from different manufacturers in which it is used.

Are these cameras equivalent when only the sensors are identical? Which aspects are important when it comes to helping users, developers and project teams select the right camera? This decision varies based on the application and requirements.

EMVA Data Are Required

![]()

Blinking pixels: example of an image artifact which is immediately noticed by the human eye.

The question of which criteria are applied when selecting a camera for a specific application is certainly not new and has also been considered by the European Machine Vision Association (EMVA). The result is the EMVA 1288 Standard. It defines methods for determining the data that define the image quality and sensitivity of an industrial camera or a sensor for such a camera.

Comparing the cameras’ EMVA data is crucial when it comes to selecting a suitable model. Only the EMVA data will reveal what a camera can do or how suitable it is.

Yet EMVA data doesn’t always fully identify problems related to the sensor design. One example of this is the so-called shutter line, an image artifact. These kinds of errors stand out immediately to the human eye, yet they do not affect the EMVA values. Another example is errors that occur at varying times, such as defective or blinking pixels.

A thorough test with a sample camera will help the user much more. What is important for such a test is to review the camera in detail and as closely as possible to the application environment/task. Not all algorithms react equally sensitively to image quality problems. In each case it’s helpful to be able to rely on an assured image quality standard, which is usually offered only by major brand-name manufacturers. This saves testing time and the tedious optimization of your own application.

A Camera’s Size, Hardware Performance and Extensive Feature Set are the Showcase.

Camera characteristics which aren’t covered by the EMVA standard also include such obvious ones as (for example) the design size and used hardware, as well as their sensitivity towards environmental influences, especially temperature and temperature changes or electromagnetic interference. These criteria could easily be deal-breakers for a camera whose data might otherwise be well suited for an application.

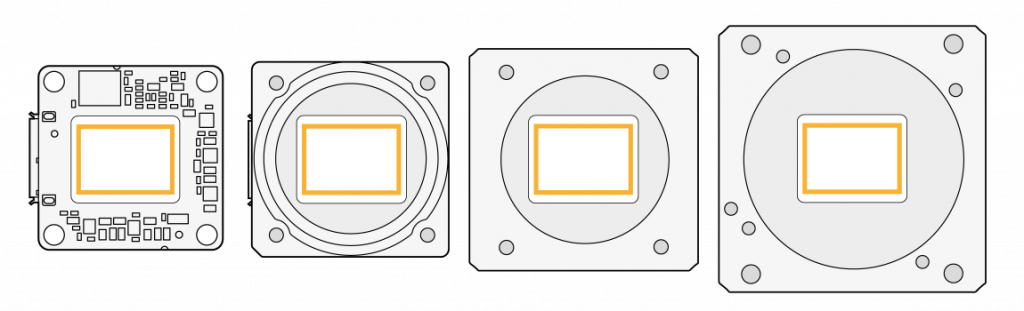

Same sensor size in differently sized housings

Identical sensors can be found in entirely different camera formats. While 29×29 dimensions and a C-mount have become the standard for sensor sizes up to 2/3” and sometimes 1” on the Machine Vision market, there are also smaller CMOS sensors in smaller dimensions or even board level variants (these are complete industrial cameras on a board without housing). Smaller dimensions offer greater flexibility and save space within the system. But since electricity consumption and heat management also need to be considered, the smallest camera is often not the most suitable one. For standard factory automation applications, these aspects are typically of prime importance. But there are also applications in other fields, such as medical engineering, where the housing must fulfill industry-specific requirements. A good feel and attractive design can also play more of a role in fields like digital microscopy, where cameras tend to be visible.

Hardware in the camera

When it comes to camera hardware, there are a variety of non-visible properties that contribute to different performance in cameras with identical sensors. This starts with the FPGA, a complex, configurable logic element which can take the form of a digital switch installed on the hardware side, ranging all the way to a specialized microprocessor. FPGAs represent the core of many camera concepts. A powerful FPGA in combination with efficient firmware makes it possible for many firmware functions (especially image optimization) to be handled within the camera, without putting additional processing load on the PC or processing board. RAM can also be advantageous for the hardware for interim storage of the images. This increases data stability and is an important factor particularly in applications that require many images in a short time and thus a high bandwidth.

Temperature/heat development of the camera

Newer CMOS sensors run at significantly higher frame rates than older CMOS sensors or CCD sensors. While this delivers better performance, it also results in higher power consumption and with it greater heat production within the camera. Higher internal temperatures in the camera can cause problems for a variety of applications and degrade image quality. For temperature comparisons between cameras, care must always be taken that the measurement is performed at identical frame rates and resolution levels. Camera design plays a major role when it comes to dissipating warmth as it is created. If this dissipation is inadequate, a temperature increase might not just raise the image noise but even damage components. Differences in the thermal design of cameras can be detected less on the basis of the absolute housing temperatures and more on temperature comparisons between the camera core and exterior housing. For temperature measurements, the camera should also be mounted (accounting for lens and geometry of neighboring objects) as it will be used for the intended application.

Bonus: Firmware Features and High Data Transmission Stability

Cameras with the same sensor can also behave very differently because the cameras’ firmware and software vary. Conformity with standards such as the GenICam would be important here ("addressing" the camera), as well as compatibility with the GigEVision and USB3 Vision interface standards. These standards regulate and define the communication channels and interfaces of the camera and reduce effort with the integration while providing reliable quality during the data transmission.

There can also be a variety of differences when it comes to the efficiency of the firmware and associated software. The first relates to the work required for the camera integration: Not all camera makers can offer mature software and driver environments for control of the camera or established programming environments (compatible with various operating systems and programming languages). These are, however, an absolute must for any major design-in.

The data stability can show additional differences. If the camera firmware is set up for a frame buffer, for example, this will enormously increase the data stability, especially with higher bandwidths/frame rates.

In large part, it is the standardized or proprietary features that can improve the performance of the vision system, although some achieve significantly better results from the same sensor.

The following offers two examples based on the Basler ace camera:

Same sensor, different data preprocessing: without (left) and with (right) image optimization through firmware.

Worthwhile firmware features of a camera include elements such as image quality optimization. This is helpful in applications that require high color fidelity (medicine), precise contours (code or number plate reading) or crisp detail in combination with color identification (component detection and placement position in the field of electronic circuit board production).

Example for use with the sequencer function

Some cameras offer a sequencer feature. During a photography sequence, this makes it possible to quickly change the camera settings from image to image according to a predefined plan. The sequencer is indispensable for emphasizing different properties of the subject over a short period. Examples include traffic surveillance, glass inspection systems and lab automation systems.

Camera Selection: Picking a Long-term “Partner”

The decision of which camera to use in a system often means settling on one partner to design around for years. Working with a large, established camera manufacturer can be a good choice.

Delivery capacity or quality aspects play a key role. A company’s ability to deliver components becomes even more important when priority is given to minimal capital commitment, the inventory situation and just-in-time delivery to avoid “waste” in the supply chain as part of a lean production process. These are demanding challenges which not all industrial camera manufacturers can meet. For the camera supplier as well, short delivery times, volatile order volumes and rapid handling of large-scale projects must be planned flexibly and well, and anchored in the company's DNA.

Reliability and stability are both essential when it comes to the camera’s quality and features. Tests and careful calibrations ensure that every camera behaves as expected and the collected data enable continuous control of the production processes.

And what happens if a camera doesn’t perform as expected? A brand's dimensions and position on the market typically reflect how a manufacturer manages quality issues, analyzing problems promptly and learning from errors to resolve problems quickly, both on the production line and for customers.