This blog post was originally published at TechNexion’s website. It is reprinted here with the permission of TechNexion.

Despite numerous rules and regulations in place, ensuring complete workplace safety still seems challenging in the industrial and commercial sectors. According to the US Department of Labor:

“4,764 workers died on the job in 2020 (3.4 per 100,000 full-time equivalent workers). Workers in transportation and material moving occupations and construction and extraction occupations accounted for nearly half of all fatal occupational injuries (47.4 percent), representing 1,282 and 976 workplace deaths, respectively.”

This shows that having necessary compliance procedures alone is not sufficient to prevent workplace hazards and accidents. We as humans had to think much beyond the boundaries of traditional safety measures.

Embedded vision has proven to be a lifesaver in this regard. By leveraging camera modules, you can not only do unmanned and remote monitoring of workspaces but many safety mechanisms can even be automated with the help of robotics and AI (Artificial Intelligence). From obstacle avoidance in autonomous mobile robots to smoke detection in factories, the use cases of embedded vision in industrial and commercial safety are plenty.

In this article, let’s learn about the most popular use cases where embedded vision has significantly improved human safety. We will not limit ourselves to people’s safety, rather, we will comprehensively cover applications that concern the overall safety and conduct of industrial and commercial facilities.

How Cameras Ensure Safety in Industrial Settings

The adoption of embedded vision is increasing every single day, especially when it comes to industrial applications. Industry 4.0 has accelerated this transformation by forcing technologists to come up with newer solutions to automate various processes. While productivity is a key focus area in Industry 4.0, more and more countries globally have started giving higher prominence to safety.

Given below are the different ways in which embedded vision helps to enhance industrial and commercial safety:

- Obstacle detection

- Theft and intrusion detection

- Ensuring worker safety during machine operations

- Smoke, fire, and leakage detection

- Automating material handling

- Automated lifting and moving

- Package and product dimensioning

- Personal Protective Equipment (PPE) detection

- Surround-view systems in industrial vehicles

Obstacle Detection

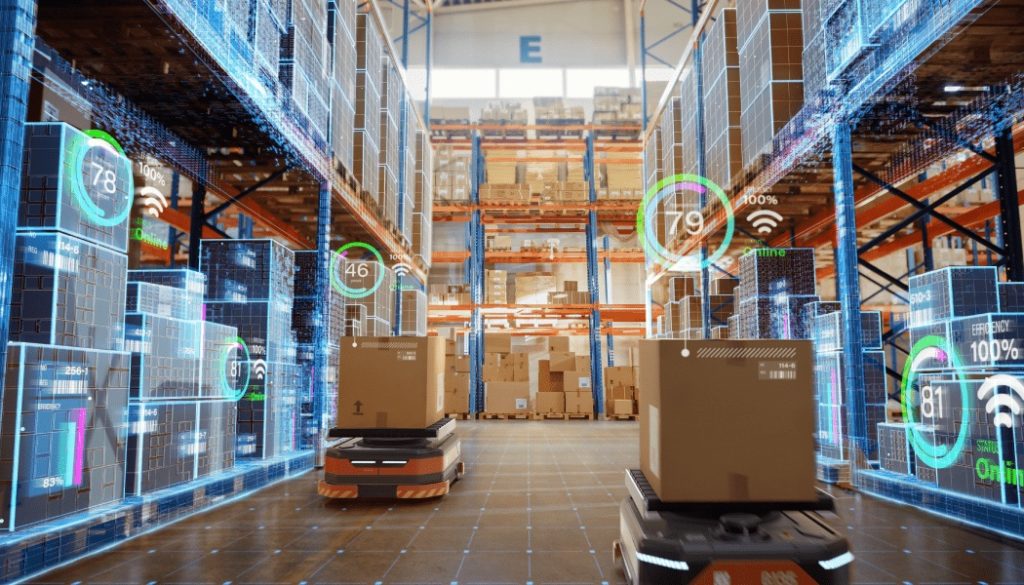

Obstacle detection is widely used in autonomous mobile robots and automated guided vehicles to enable easy navigation without collision and accidents. These modern-day vehicles leverage a combination of embedded cameras and AI (Artificial Intelligence) to detect obstacles in their field of view. While cameras capture images and videos, the AI algorithms analyze them to detect any objects and send a trigger to stop the robot. This ensures that robots and drones don’t run into anything unnecessarily.

However, obstacle avoidance systems of today employ even more advanced algorithms to be able to differentiate between human and non-human objects. This makes sure that humans in workplaces and public places are safe all the time.

Theft and Intrusion Detection

Smart surveillance systems are deployed in warehouses, office buildings, construction sites, etc., to prevent the presence of undesired people on their premises. This is achieved primarily by two ways:

- Smart surveillance and security cameras

- Patrol robots

In the former, embedded cameras are installed in key points in the area to automatically identify any theft or intrusion. In the case of the latter, an autonomous robot moves around the area – just like a human – to detect unwanted objects or people. Cameras that can capture high-quality images during the day as well as at night are used in such robots to ensure 24×7 surveillance.

In both cases, artificial intelligence algorithms can analyze the image and video feed sent by the camera system to detect undesired activities completely automatically.

Ensuring Worker Safety during Machine Operations

According to the Occupational Safety and Health Administration, workers who operate and maintain machinery suffer approximately 18,000 amputations, lacerations, crushing injuries, abrasions, and over 800 deaths per year in the US alone. While professional training has helped to prevent accidents to some extent, it is automation that has made a notable improvement in the safety of machine operators.

Using vision for automating safety mechanisms is a game changer in this regard. Following are a few ways in which this is done:

- Using an embedded vision or machine vision camera to detect the presence of a human near a machine, especially the dangerous parts. Here, the camera monitors certain parts of the machine continuously while the AI/ML algorithm detects the presence and sends an alert to the machine to switch off (An example is an automated metal punching machine. Humans should stay away from its arm during operation).

- Cameras can prevent machines from falling off their pedestals by proactively detecting possible breakdowns or interruptions. This gives peace of mind to the people working with the machine.

- Cameras can ensure that workers maintain proper distancing from machines by measuring the distance between them using a combination of 2D and 3D imaging technologies.

Smoke, Fire, and Leakage Detection

One of the biggest challenges in traditional smoke and fire detection systems is the speed of reaction. Since they work purely based on heat variations, even the most sensitive detectors can detect fire only once it becomes ‘visible’ or starts to spread. On the other hand, embedded cameras can spot early signs of smoke and fire by using a combination of thermal, visual, and IR (InfraRed) sensations. AI-based computer vision algorithms quickly react to this by identifying the threat instantly.

Gas and fluid leakage detection also happens in a similar fashion where issues can be identified in the first few seconds of (and sometimes even before) it occurs. This can be life-saving in large gas, thermal, and nuclear power plants. They are also extremely useful in turbines, water transportation & sewage systems, and gas pipelines.

Automating Material Handling

Material handling is one of the major reasons for workplace accidents in industrial settings, especially that of heavy items. Robots have transformed material handling in warehouses, factories, and construction facilities by completely automating the process. Advanced goods-to-person robots are capable of autonomously navigating to designated locations to identify, pick, and place objects onto their storage cabinet and take them to their respective destinations. Robots use embedded cameras and computer vision to perform these tasks.

Automated Lifting and Moving

Lifting and moving is a type of material handling where specialized equipment like forklifts are used to handle heavy objects. Conventional forklifts require a human driver to operate them. Embedded vision has made it possible to automate this process by using multi-camera systems that enable obstacle avoidance, localization, path planning, and surround view. These cameras can also locate the exact coordinates of the objects to be moved.

Package and Product Dimensioning

Similar to material handling, measuring the dimensions of heavy objects can often lead to accidents. These objects can vary from small boxes to large cartons that are a few tons in weight. Doing it manually is a time-consuming process too.

Embedded cameras have made a breakthrough here by making it possible to automatically measure the dimensions of objects. Today, automated measurement is mostly carried out for objects like boxes or rods that are less complex in shape.

Automated dimensioning is made possible by using 3D depth cameras where a 3D map of the objects is created. The most popular 3D imaging technologies used for this purpose today are stereo, structured light, and time of flight.

Personal Protective Equipment (PPE) Detection

According to Safety Toolbox, a study by the National Safety Council found that workers who wore PPE (Personal Protective Equipment) reduced their risk of eye injuries by 90%, head injuries by 85%, and foot injuries by 60%. Despite this realization, many industrial workers don’t prefer wearing protective outfits. In addition, a small percentage of those who wear them do not follow the right protocol – knowingly or unknowingly.

Since it is not practical for supervisors to monitor workers all the time, an effective alternative is to use cameras to analyze if all the workers are wearing PPE equipment as per the desired standards. It is the combination of embedded vision and artificial intelligence that does the magic here too.

Surround View Systems in Industrial Vehicles

Large and heavy industrial and commercial vehicles like mining vehicles and trucks often face the challenge of having multiple blind spots where the driver is unable to get a clear view of their surroundings. This happens because of their size and complex structure. This can be overcome by using a 360-degree surround view system fitted with cameras on all sides of the vehicle.

These are multi-camera systems that come with a minimum of 4 cameras that give a complete view of the front, rear, and two sides of the vehicle. In the case of large industrial vehicles, there are often blind spots even on the front side owing to their width or height. A surround view system eliminates all these and hence reduces the risk of accidents and collisions considerably.

Closing Words

With more regulatory bodies introducing stricter policies to ensure workplace safety, the demand for vision-based safety solutions is likely to rise in the future. Hence if you are into building and integrating industrial machinery and equipment, it is high time that you think about building a camera-enabled industrial safety device. Whether you are starting to build one or upgrading your existing industrial embedded vision system, TechNexion can help.

We bring to the table more than 2 decades of experience in the embedded systems space with unmatched engineering expertise. Our camera solutions are suited for industrial use with features such as high-temperature resistance, low heat dissipation, and IP-rated enclosures. Visit the embedded vision cameras page to learn more about our vision solutions.

VLS3-AR1335-CB

VLS3-AR1335-CB