Refractive lenses are one of humanity’s oldest and most ubiquitous technologies. They have developed to dizzying levels of sophistication in the last few hundred years, with today’s tiny, high-quality lens assemblies found in smartphones often costing less than a dollar to produce.

In contrast, metalenses only saw their commercial debut in 2022, yet IDTechEx‘s report, “Metamaterials Markets 2024-2034: Optical and Radio-Frequency“, forecasts a multibillion-dollar market for these flat optics within ten years. Much of this predicted growth is down to the potential metalenses have to make computer vision more powerful.

Shrinking lenses down

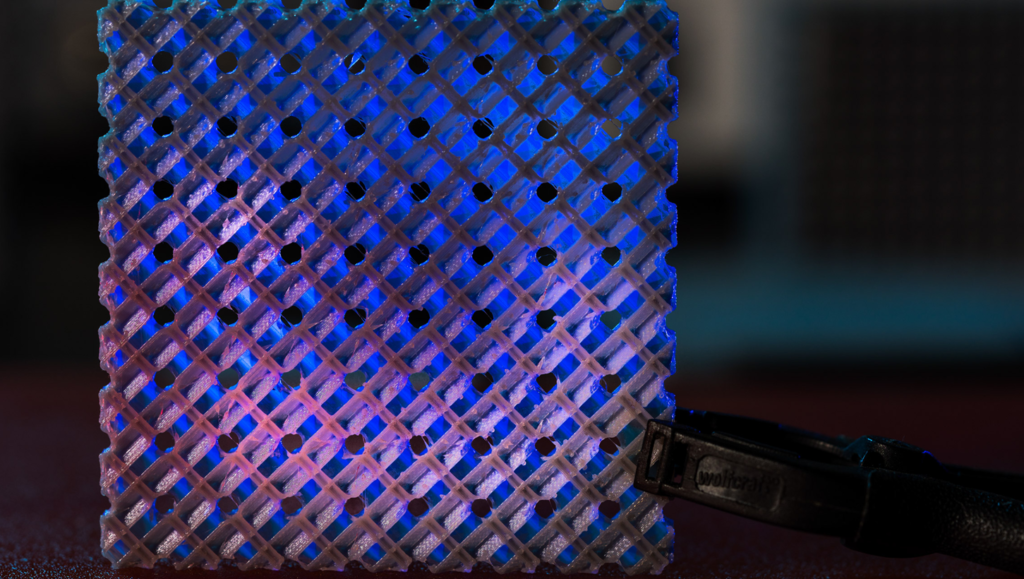

Multiple conventional lens elements can be replaced with one metalens, shrinking optics while reducing costs.

Instead of using the curved geometry of a refractive material to focus light, metalenses use nanoscale patterns of “meta-atoms”, which are typically patterned via standard semiconductor industry processes like DUV lithography. This could simplify image sensor supply chains by allowing optics to be produced in the same facilities as sensors.

However, the greatest benefit is that, unlike refractive or diffractive optical elements, metalenses can perform near-arbitrary transformations to wavefronts of light. A single metalens can generally be used where multiple “conventional” optical elements are needed to control optical aberrations and render images acceptably. This could reduce the cost of advanced optical systems while reducing their size and adding new optical capabilities.

To give one example, the FaceID sensors used in iPhones produce a 3D scan of the face by projecting a dot pattern from an IR laser onto the face. In structured light projectors like this, a single metalens could do the same job as several diffractive and refractive lenses while improving imaging performance, reducing temperature dependency, and improving signal-to-noise ratio.

Harvard spinout Metalenz was the first company to commercialize metalenses, with STMicro using its lens designs in some of its time-of-flight sensors since 2022. In 2023, Metalenz announced two customers for its Orion dot projectors, Dilusense and Vertilite. These are expected to be used in facial biometric systems and represent the second known commercial application of metalens technology. These dot projectors may well outperform existing options in terms of price as well as optical performance.

New imaging possibilities

The capabilities of metalenses go beyond simply replacing today’s optics. Metalenses are sometimes labeled as gradient index lenses. To vastly oversimplify, the meta-atoms are small enough relative to the wavelengths they interact with that the waves cannot “see” the individual structures, so packing the meta-atoms more densely gives the material a higher refractive index. However, this obscures the full potential of technology. Meta-atoms can be resonators, waveguides, or half-waveplates (which modify the polarization state of light), so they can be highly selective depending on wavelength, polarization state, and more. The upshot is that by harnessing these different methods of modifying phase, metalenses can perform optical functions that would be impossible or prohibitively bulky and costly to achieve with “conventional” optics.

Metalenz’s Polar ID face unlock system may be the first technology to demonstrate this possibility commercially, offering a competitor to Apple‘s FaceID system for use in Android phones. An IR flood illuminator can be placed right next to a camera, which uses a metalens to form an image. The metalens splits the image of the face into multiple polarization components; achieving this with conventional optics requires several beamsplitters and filters and would be too large and expensive to use in a smartphone.

Since human faces have unique polarization signatures, Metalenz says this system easily detects spoofing attempts with 2D images or masks while having a higher spatial resolution than competitor systems. Structured light sensors require the projector to be spatially separate from the camera, which is responsible for the notch in iPhones. This is not the case with Polar ID, which is also expected to be substantially cheaper. Polar ID appears to be gearing up for production, and it seems highly likely it will make its way into smartphones soon.

Towards the visual spectrum

Commercial metalenses so far have been designed to operate with single-wavelength illumination in the IR spectrum, but in the future, they could replace a wider array of camera lenses, both for computer vision purposes and for photography and videography. Optimizing metalens design for achromatic (full color) performance is arguably still a work in progress. However, a solution has already emerged for patterning visual spectrum metalenses, which require smaller feature sizes than IR metalenses due to the shorter wavelengths involved.

Utah-based nano-optical component supplier Moxtek has set up a metasurface foundry, which it believes is better suited to visual spectrum metalenses than the DUV lithography processes employed by other metalens manufacturers. Moxtek uses nanoimprint lithography (NIL), stamping the meta-atom pattern into a resist before etching it into a high-refractive index material. This is capable of recording smaller features than DUV, which Moxtek says is not reliably capable of patterning down to the scale required for visual spectrum metalenses. This well-proven process is also expected to be more cost-effective than the EUV lithography used in the latest semiconductor nodes.

Further insights

Given that metalenses entered the commercial market so recently, the scope for their technological development and growth into further applications in computer vision and beyond is huge. IDTechEx has been studying emerging materials and photonics technologies and their market opportunities for a decade, utilizing extensive primary research. Their report, “Metamaterials Markets 2024-2034: Optical and Radio-Frequency” is now in its second edition. Providing an in-depth understanding of the underlying technologies, manufacturing methods, and application opportunities, it explores the trajectory of the metalens market, in addition to other important electromagnetic metamaterial technologies, including reconfigurable intelligent surfaces and radar beamformers. It is essential reading for those wishing to build a comprehensive picture of this exciting space.

To find out more about this IDTechEx report, including downloadable sample pages, please visit www.IDTechEx.com/Meta.

Sam Dale

Senior Technology Analyst, IDTechEx

IDTechEx provides trusted independent research on emerging technologies and their markets. Since 1999, we have been helping our clients to understand new technologies, their supply chains, market requirements, opportunities and forecasts. For more information, contact [email protected] or visit www.IDTechEx.com.