This blog post was originally published at Avnet’s website. It is reprinted here with the permission of Avnet.

The MCU is a low-power, flexible and highly integrated device. It has inspired many peripherals, from clocks to timers, as well as data conversion and power management. Most MCUs incorporate plenty of general-purpose interfaces (GPIO), along with industry-standard bus interfaces. Recent additions include capacitive touchscreen controllers, wireless transceivers, and high-speed digital interfaces.

As the list of microcontroller features and capabilities grew, so did the list of applications. MCUs have become the go-to computational device for every embedded design, incorporating energy-efficient computing resources, interfacing, advanced security, data conversion, and connectivity within a single compact, low-cost package.

Microcontrollers in automotive applications

With its versatile and flexible features and functions, the automotive industry was an early adopter of the MCU. As vehicles became more stylish and able to cover longer distances, increasing comfort and body control functionality was a natural fit for the microcontroller. Today’s vehicles use MCUs by the hundred, controlling everything from mirrors, seat positioning, anti-lock brakes, instrument clusters, and the touch-controlled infotainment system.

Microcontroller advancements continue to push the boundaries of processing performance, energy efficiency, and functional integration. High-end units with multiple cores are considered crossover devices, combining microcontroller functionality and microprocessor performance at MCU prices.

These advanced MCUs typically feature extensive connectivity features. These include automotive-specific protocols such as Local Interconnect Network (LIN) bus and CAN (controller area network) interfaces, along with protocols that originated in other verticals, such as USB, Ethernet, and MIPI (mobile industry processor interface). Ethernet over a single twisted pair, or Single Pair Ethernet (SPE) was developed for the automotive market but is now also popular in the industrial sector.

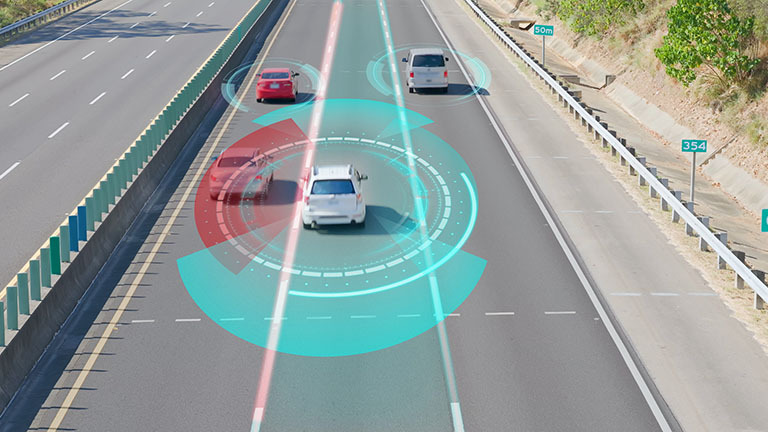

Many advanced MCUs and crossover devices are suitable for advanced driver assistance systems (ADAS), like adaptive cruise control, emergency braking, lane assist, and blind-spot detection. Building automotive ADAS applications such as lane tracking, distance estimation, and object detection relies on different sensor types. MCU-based sensor fusion brings together data from cameras, radar, and lidar sensors.

Adaptive cruise control relies on data from several sensor types. This high bandwidth data must be streamed and processed in real-time to provide the control needed by advanced driver assistance systems.

MCU interface capabilities

Virtually every MCU has some form of peripheral connectivity, ranging from simple, bit-addressable GPIO pins to industry-standard high-speed serial bus interfaces such as SPI, I2C, and UART. I2C and SPI are popular for interfacing with peripheral ICs and modules.

Examples include MEMS accelerometers, temperature and humidity sensors, small OLED displays, and power management ICs. For convenience, most analog sensor elements, such as a MEMS accelerometer, are packaged with a custom application-specific integrated circuit (ASIC) that takes measurements from the sensor element, converts, and normalizes the data, and places it in serial bus registers. Using SPI or I2C, the host MCU can interrogate the registers and transfer the measurements.

While the above interfaces offer a high degree of connectivity, the limiting factor for more sophisticated ADAS functions is data rate and transfer distances. I2C, UART, and SPI interfaces are more suited to intra-system connectivity applications, but ADAS sensors are typically packaged as automotive OEM sub-systems and may need to interact with one or more electronic control units (ECUs) to deliver a single ADAS function.

For example, an adaptive cruise control (ACC) feature requires a forward-looking radar or lidar module to scan for vehicles or obstacles ahead. It must interact with both the braking ECU and the engine ECU. Increasingly, the automotive trend is to utilize radar sub-systems for short distances and speed detection, and lidar for longer distances and enhanced spatial resolution.

The radar/lidar module will stream large quantities of data to the ACC control unit in real-time and is located at least a meter’s cable length from the ECUs. Typically, for high bandwidth video-based applications, such as a camera used for ACC, the sensor is placed separate to the corresponding ECU. Serializer and deserializer ICs will convey the video stream through a flexible and lightweight cable to the ECU.

Specialist video processing SoCs are utilized to interpret and detect objects using algorithms in real-time. Increasingly, this data is combined with other data streams using sensor fusion techniques. The high bandwidth nature of any camera-based system requires data conveyed using Gigabit Ethernet or high-speed CAN network interfaces. A connection using LVDS (low-voltage differential signaling) may be used to feed video to the cockpit display, for example, a reversing camera.

Fast cars need fast sensor data

Radar and lidar sensor modules are increasingly used for a wide range of ADAS applications and are typically divided into long-range and medium/short-range use cases. Long-range applications include ACC and collision warning, and short-range examples are parking assistance and blind spot detection. Considerable processing power is required for long-range object detection, requiring high-performance embedded processors. 1000Base-T1 Single Pair Ethernet (SPE) and CAN interfaces provide connectivity to associated ECUs and a sensor fusion ECU.

As already highlighted, sensor fusion is an increasingly vital function, particularly for semi-autonomous vehicles, and crucial for full autonomy. Although each ADAS sensor is a dedicated system, combining the data, either in a raw or preprocessed format, allows a complete picture of the vehicle’s position relative to other objects.

It is no accident that microcontrollers are well-suited to a wide variety of automotive use cases. With such a broad range of performance, interface and connectivity options, they easily integrate with something as relatively simple as sensor ICs for seat comfort controls. But they are just as capable of being the foundation for sophisticated automotive ADAS sub-systems, such as forward-facing collision avoidance radar modules.