Robotics is a key development focus area for embedded vision…err…visionaries. Perhaps the most popular robot line currently available for sale is the Roomba vacuum cleaner series and closely related Scooba floor scrubbers, designed and manufactured by iRobot (who, not coincidentally, is also a leading producer of military robotic systems). However, Roomba's visual acuity is at best limited.

All models contain infrared 'cliff' sensors, located underneath the front 'bumper', to prevent the Roomba from driving itself off steep edges such as the lip of a stair step. Optional infrared-transmitting 'Virtual Wall' accessories interact with another infrared sensor, this one omnidirectional and mounted at devices' top front center locations, to prevent Roombas from crossing the IR beams into designated areas. And that same top-mounted infrared sensor also finds use, in second-generation and newer Roomba models, to assist the robotic vacuum cleaner in returning to its docking station for recharging once it's concluded the cleaning task.

But the predominant means by which a Roomba navigates through a room is through trial-and-error, in conjunction with the earlier mentioned impact 'bumper' which signals the device that further forwards travel is not possible. This approach is algorithmically simplistic and therefore leads to low cost implementations, but it also has downsides, as Wikipedia notes:

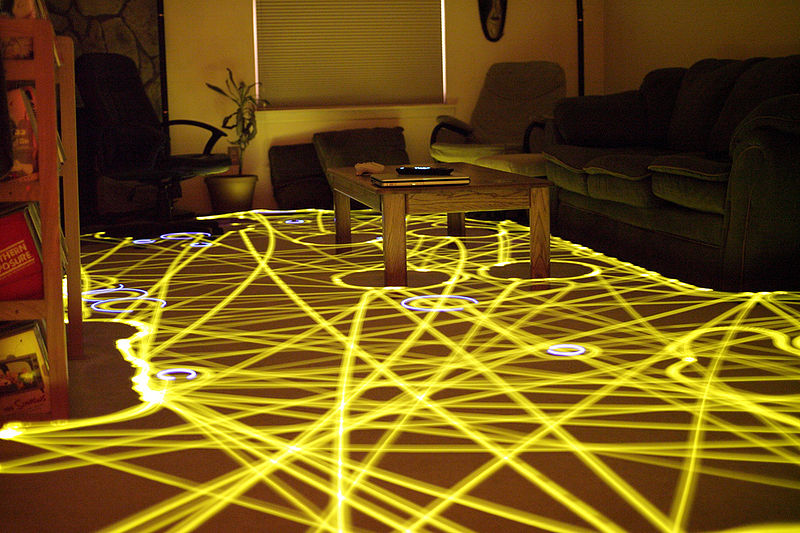

Roombas do not map out the rooms they are cleaning. Instead, they rely on a few simple algorithms such as spiral cleaning (spiraling), room crossing, wall-following and random walk angle-changing after bumping into an object or wall. This design is based on MIT researcher and iRobot CTO Rodney Brooks' philosophy that robots should be like insects, equipped with simple control mechanisms tuned to their environments. The result is that although Roombas are effective at cleaning rooms, they take several times as long to do the job as a person would. The Roomba may cover some areas many times, and other areas only once or twice.

A more robust approach would leverage embedded vision technology to map the room as it's being traversed, not only remembering the locations of obstacles but also recalling regions that the robot has already traveled through in order to avoid unnecessary path repetition. As such, I'd like to draw your attention to the new (Volume 27) edition of Make Magazine, which just showed up in my mailbox a few days ago. As the publishers note:

The Robots have returned! MAKE Volume 27 features a special package with robotics projects for every age and skill level. They play music; they spy via the internet; they outwit your pets; they learn from their mistakes!

A subset of the print content (which, among other things, discusses a vision-augmented Roomba) is already available on the website, with more progressively appearing in the coming weeks. However, if you're an employee of Taiwan-based Foxconn, I'll certainly understand if you're not enthused to learn more about robots. That's because, as was widely reported in cyberspace over the past 24-or-so hours, the company's CEO recently announced to mainland China-based subsidiary employees at a 'corporate dance party' (believe it or not) that a goodly percentage of them would be replaced within the next three years by 1 million robots that Foxconn planned to bring online.

While still with EDN Magazine, I traveled to Taiwan two sequential summers to visit with companies there. During the second trip, I published an admittedly critical writeup that, among other things, expressed surprise at the lack of assembly line automation I found. Instead, what I instead found were lots of young women working long hours doing mind-numbing soldering and other tasks, often in dimly illuminated and poorly ventilated facilities, and frequently wearing wrist braces indicative of repetitive strain injuries. And, when even lower cost labor was needed, Taiwanese companies would obtain it via contract labor from Malaysia, Thailand and elsewhere, with employees housed in cramped dormitories next door to the manufacturing facilities. Suffice it to say that my Taiwanese hosts were not terribly pleased with my editorial angle, and I didn't get invited back for a third visit.

Robots are the inevitable next step in this labor transition. They don't eat. They don't sleep. They don't get paid. They don't commit suicide in response to stress. And they don't leak client secrets. Foxconn already harnesses 10,000 robots for simple tasks such as paint spraying, welding, and assembly, and I presume the experiment has been a success so far, judging from the energetic expansion plans. A transition from human labor to autonomous robots might make fiscal sense, but does it make moral sense? This time, I'll leave that one for you to judge. I welcome your thoughts in the comments section of this post.

For more perspectives on the Foxconn news, check out the following links:

· Engadget

· Gizmodo