"With the LabVIEW platform, we can easily adapt to different process requirements and adapt the software for future enhancements."

– Danny Hendrikx, Sylvania Lighting International

The Challenge

Building an accurate and flexible research and development production machine for a new, smaller type of metal halide lamp.

The Solution

Integrating NI vision and motion control technology into a flexible program to control the production machine and easily adapt and modify the steps in the production process.

Sylvania Lighting is one of the world’s largest artificial light source manufacturers. We have a broad product offering, from incandescent light bulbs, halogen, and low-energy lamps for the consumer market to fluorescent lamps, high-intensity discharge (HID) lamps, and various special products for professional use.

At the Sylvania plant in Tienen, Belgium, we produce and develop metal halide lamps. To develop a new, smaller type of lamp, we needed a production machine that would let us easily adapt all process parameters. The standard “pinch process,” in which two metal blocks press melted glass around electrode-foil wires to create an impermeable bond, is not capable of producing these new lamps. Therefore, we developed a new process to melt the glass directly around the foil, requiring a totally new machine and a new, optimized production process.

One of our requirements for the new system was that developers be able to change the process steps and their parameters, as well as the order of the steps. Our developers also wanted to build their own sequential programs from the different process steps. An operator needs to run the completed automated program to call the process steps in the required order and give handling instructions to the operator. The machine also must be flexible in order to produce a wide range of lighting products, and should allow easy and quick setup to facilitate changing from one type of light bulb production to another.

Existing PLC systems do not offer this kind of flexibility, so we decided to develop our own system based on a Windows PC architecture and National Instruments hardware and software.

Implementation of the New Production System

National Instruments helped us consider our options given our requirements, including interfacing to both servo and stepper motors and controlling a CO2 laser using a pulse-width modulation (PWM) signal, along with the need for an overlooking security mechanism. We decided to use a PC architecture with three National Instruments boards – an NI PCI-7831R reconfigurable I/O device, an NI PCI-7356 high-performance stepper/servo motion controller, and an NI PCI-8252, IEEE 1394 Board with Vision Acquisition SW to interface with a digital camera. To develop the software, we used National Instruments LabVIEW, NI Vision Assistant, and NI LabVIEW FPGA Module.

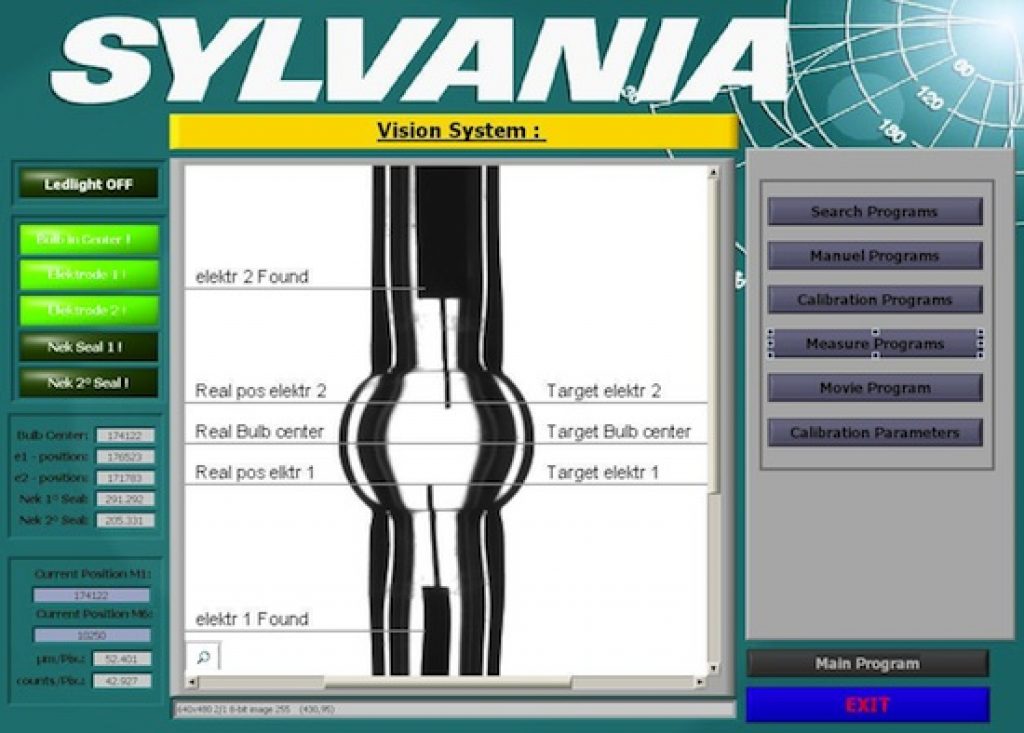

The new system uses a Basler digital IEEE 1394 camera connected to the PCI-8252 board to take images of the glass bulb. Using algorithms developed previously in NI Vision Assistant and migrated to LabVIEW, we can measure the center of the bulb and the exact location where the electrodes need to be placed. The bulb is then aligned using a linear servo motor capable of traveling 30 cm with 1.2 µm accuracy. The glass is heated during this delicate process using a CO2 laser, which is directed using an optical system aligned by a second linear servo system, also with 1.2 µm accuracy. The PCI-7356 board controls the servo motors and the two stepper motors that place the electrodes in the bulb and manipulate the foil. The PCI-7831R controls the CO2 laser with a 5 kHz PWM signal, and controls and monitors all safety requirements and emergency stops.

LabVIEW graphical programming is at the heart of the system. Each function, including PID control and burner time, is implemented separately, and can be called manually or automatically. A recipe can be created in tabular format that calls these different functions sequentially.

Future Plans

By integrating vision, motion control, and the laser control into a PC-controlled system, we can easily adapt to different process requirements and process recipes. In addition, with the LabVIEW platform, we can also adapt the software for future enhancements. In a future version, we plan to measure the volume of the light bulb for statistical analysis, using the same camera that we currently use for positioning the electrodes.

Author Information:

Danny Hendrikx

Sylvania Lighting International

Soldatenplein 13

Tienen B-3300

Belgium

Tel: +32 (0) 16 800211

Fax: +32 (0)16 818945

[email protected]