This market research report was originally published at Yole Développement’s website. It is reprinted here with the permission of Yole Développement.

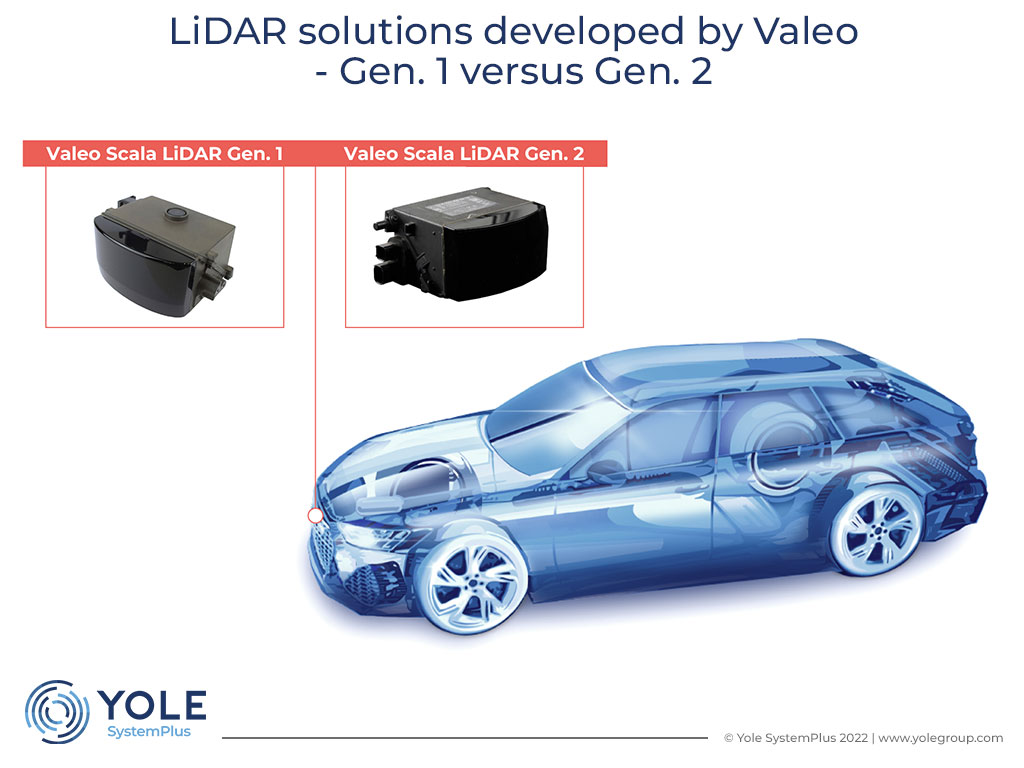

Four years after Valeo’s first-generation LiDAR was implemented in a commercialized car, the French company announced last December that its second-generation LiDAR will equip the new Mercedes-Benz S-Class, reaching level 3 of autonomous driving. Although still too exotic for mass-produced car manufacturing, this type of high-resolution sensors could, with the clever integration of cameras and radars, help to reach higher qualification levels for self-driving cars.

Backed by its strong expertise in reverse costing of innovative automotive systems, Yole SystemPlus, part of Yole Group unveiled the detailed profiles of Valeo’s LiDARs in a complete set of automotive Teardown Tracks, available on a dedicated platform: Here. Through its investigations, Yole SystemPlus highlights the most striking points raised from the comparison between Scala 1 and Scala 2.

LiDAR: the emerging technology to improve road safety

A strong development effort is being made by car manufacturers to eliminate traffic accidents and improve road safety. This involves the integration of several types of sensors to detect moving objects around the vehicle to efficiently initiate an emergency braking system. The most common sensors used so far in commercialized cars are cameras and radars. However, standing by these technologies is not enough and LiDAR, featuring large fields of view and good angular resolution, has a role to play in reaching new levels of safe object identification. The growing interest for 3D laser scanner implementation in cars is confirmed by Yole Intelligence’s market overview, the LiDAR 2022 – Focus on Automotive and Industrial report, showing that ADAS is expected to drive large volumes of LiDAR with 4.5 million units in 2027, representing a CAGR of 87% between 2022 and 2027. Yole Intelligence and Yole SystemPlus are closely working within Yole Group to offer a global vision of technologies related to semiconductors and their evolution.

Valeo Scala generation 1 vs generation 2

There is great interest in taking a closer look at the second-generation Valeo Scala LiDAR as no other scanner has passed the automotive-grade qualification since the first version in 2017. From table 1, the noteworthy difference between the two generation specifications lies in the total points scanned per second, which increases from 58 000 to 260 800. In addition, the vertical scan angle has grown by a factor of four with a significant decrease of the angle resolution from 0.8° to 0.6° obtained thanks to a more refined zone grid. The imaging technology based on traditional mechanical scanning with rotating mirrors remains unchanged.

To better understand what is behind one of the few LiDARs implemented in a commercialized car, Yole SystemPlus conducted a teardown of these two generations of scanners. The tracks of Scala 1 and Scala 2 include respectively around 50 and 90 high-resolution pictures describing step by step the dismantling of the system and the electronic boards. In each case, approximately twenty integrated circuits were the subject of a specific analysis (X-Ray analysis of optical casing and chips for instance). From this teardown, a very detailed bill of material was established. Table 2 describes some of the chips included in the core of the electronic systems and gives a good overview of the actual key players in the market. In terms of performance, it confirms the company’s desire to focus its development efforts on improving resolution, which requires more powerful modules to collect, process and store a cloud of points 4.5 times larger than the previous generation.

Opening the systems reveals that Scala 1 includes 780 active and passive components while Scala 2 contains 890. The cost of the electronic core system calculated using costing tools specifically developed by Yole SystemPlus is estimated at $70 for the first-generation scanner and $110 for the second.

A source of technological innovations

As an emerging technology, LiDAR offers great potential for exploring numerous architectural options. Yole Intelligence points out that traditional mechanical scanning represents 71% of design wins. MEMS micromirror and Flash LiDAR with VCSEL as a potential light source are already making their way into the automotive industry. In the long term, Optical Phased Array LiDAR still needs to resolve component integration issues before seeing the light of the day in the next couple of years.

Concerning the ranging method, Time-of-Flight (ToF) represents 100% of design wins. However, more sensitive approaches are in the limelight with the introduction of Frequency Modulated Continuous Wave (FMCW) LiDAR that not only detects the distance and direction of objects but also measures their moving speed.

Valeo has already revealed its current development work on a third-generation product advertised with a resolution nearly 50 times that of the second-generation device. Yole SystemPlus remains alert on the subject to continue its investigation on the evolution of Valeo’s automotive-grade LiDAR. Meanwhile, the team is currently working on Denso’s LiDAR using a similar approach than Valeo and will unveil the complete profile of this new 3D scanner within the next few weeks.

Wilfried Theron

Director of Electronic Systems Department and Quality Manager, Yole SystemPlus (part of Yole Group)